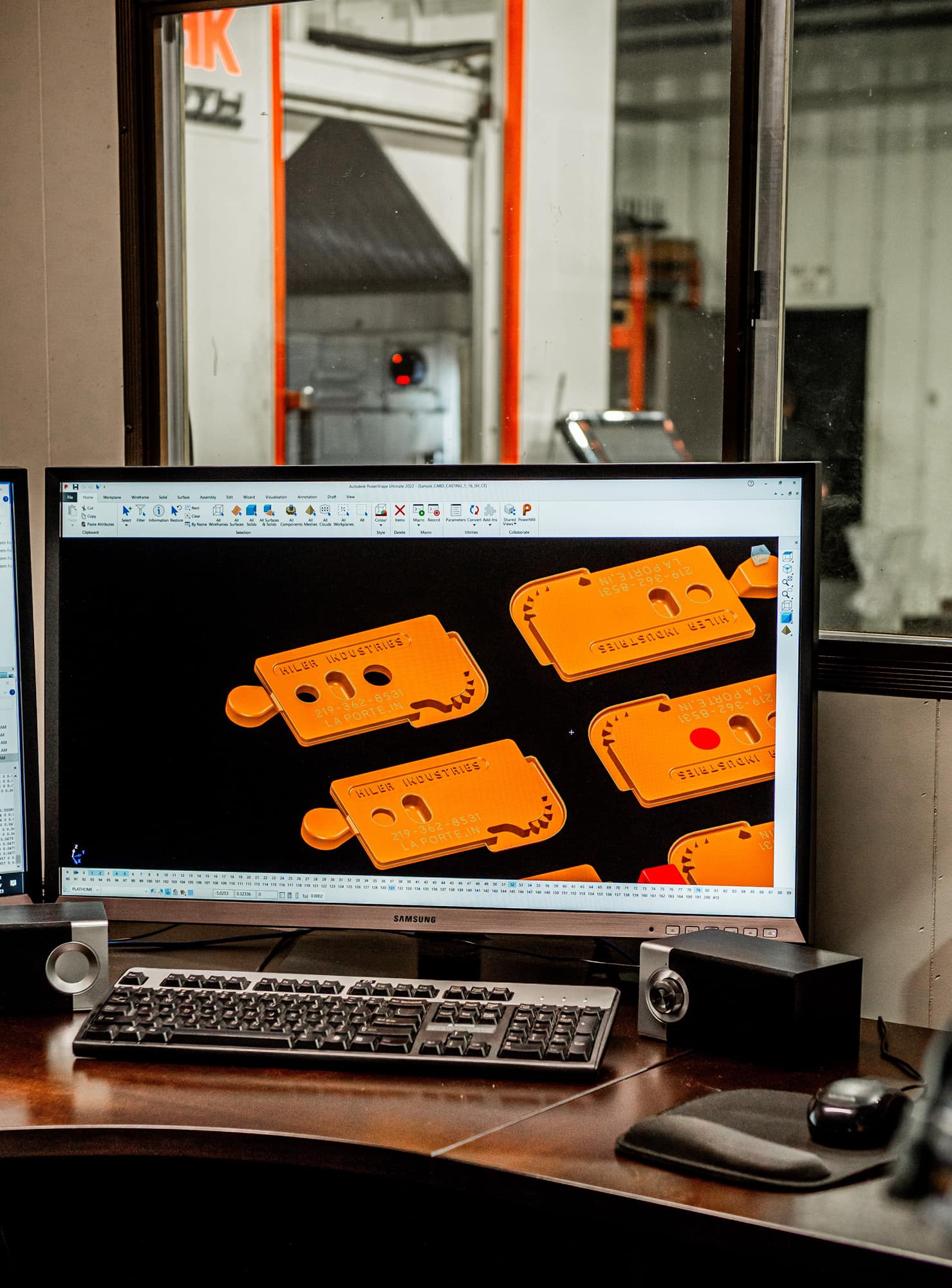

From simple to extremely complex casting designs, our pattern shop makes designs that ensure your final castings meet all your specifications.

Our In-House Pattern Shop Offers:

- CNC-machined patterns that provide close and consistent casting tolerances

- Reduced processing time from prototyping through production

- Solidification capabilities to ensure optimal metal flow and efficient gating

- In-house 3D scanning capabilities that provide dimensional verification for sampling purposes with our Creaform HandySCAN 700 equipment