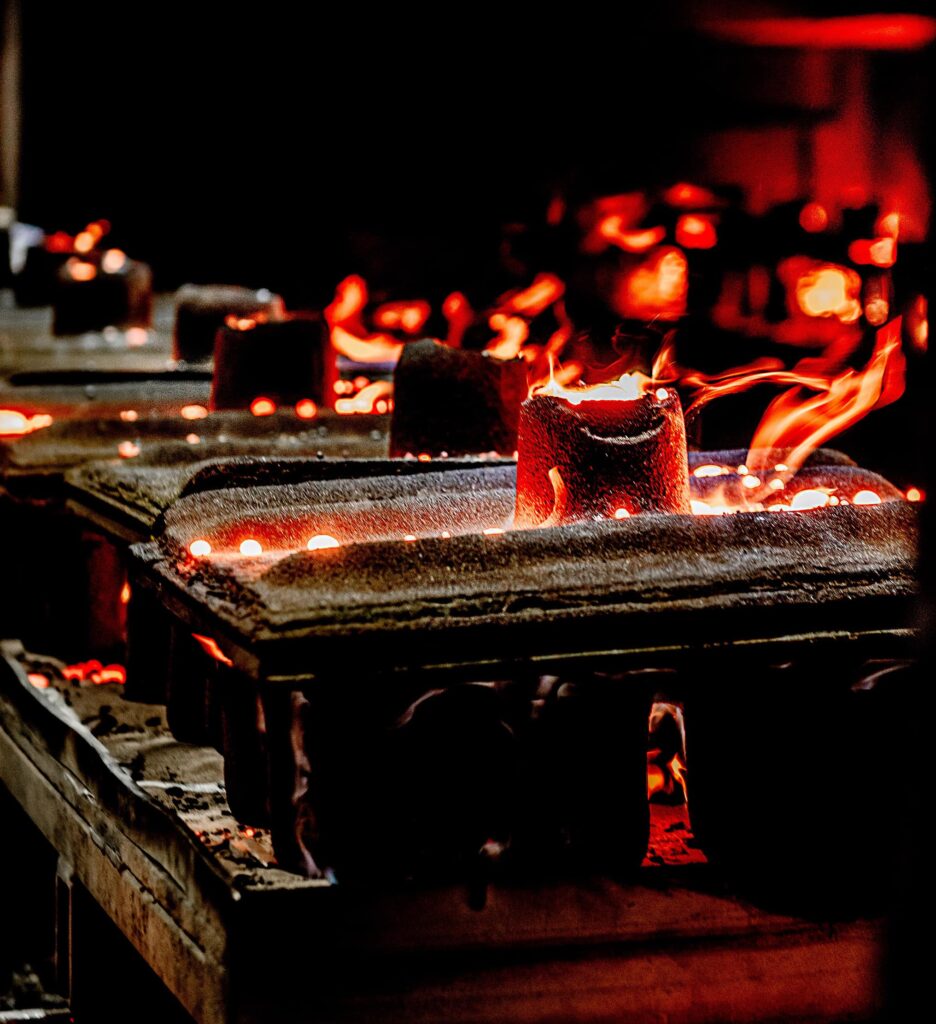

Top-of-the-Line Casting Solutions

Hiler Industries specializes in producing high-quality castings using a range of materials, including ductile iron, gray iron, and alloyed irons. With advanced capabilities in shell mold casting, we ensure precision and durability for diverse applications.